I Love these guitars. Their Quality control isn’t great, but there’s nothing that can’t be fixed. A bone nut will help the sustain and keep it in tune…

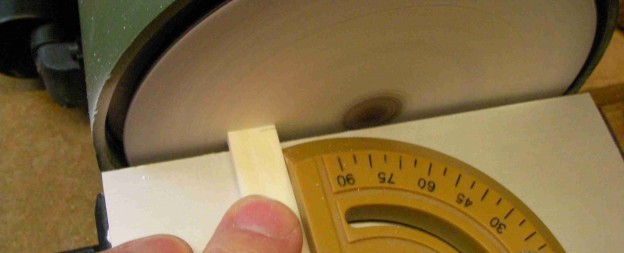

I’m going to use a large blank…. This one is already nice and square which saves a little work.

This one is already nice and square which saves a little work. It’s a little thick mind you, so I’ll need to grind it down a little…

It’s a little thick mind you, so I’ll need to grind it down a little… Fits the slot nicely now…

Fits the slot nicely now… Next the length to fit the neck width..

Next the length to fit the neck width.. and round off the top a little.

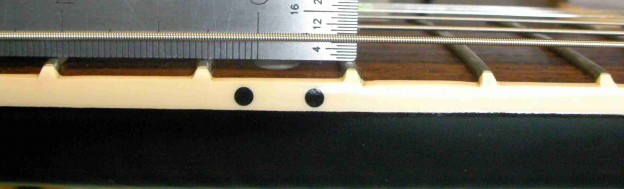

and round off the top a little. With the basic shape done mark up the string slots…

With the basic shape done mark up the string slots… Before I fit the strings I gave the fret-board a good clean…

Before I fit the strings I gave the fret-board a good clean… and oil…

and oil…

Once that’s done all it needs is a standard setup.

First the neck set…. A little high so a small tweek on the truss-rod….

A little high so a small tweek on the truss-rod…. Then the action measured at the 12th fret, again just a little high..

Then the action measured at the 12th fret, again just a little high.. so drop the bridge a little….

so drop the bridge a little….

The action at the 1st fret will need to be taken down. I only put shallow notches for the strings at first as it’s impossible to tell how deep to cut then until the strings are fitted and at full tension. So now out with the nut files to get the action right…

So now out with the nut files to get the action right…

Now the Intonation, shouldn’t need much since I’ve not changed the string gauges, assuming it was properly to start with! Lastly the pickup heights. Again they shouldn’t need doing but I want to make sure the outputs are balanced.

Lastly the pickup heights. Again they shouldn’t need doing but I want to make sure the outputs are balanced. There we are, ready for action…

There we are, ready for action…

A few words from the owner:

“I took my 335 to George as it just wouldn’t stay in tune for more than five minutes, had a horrible action and was an all round pig to play. I’d wanted a 335 since being a youth and this guitar was supposed to be the purchase of a lifetime! A real disappointment when buying an expensive guitar.

George knew exactly what to do and now it plays as I’d imagined it would as a youth. Thanks George you did a grade A job.”