A chap came to see me with an upgrade he has had a problem with. It seemed like an easy job, fit a new neck on to an old body.

This is as far as the screws got before they jammed solid and tore the heads out…

The problem is the holes in the body don’t line up with the holes in the neck…

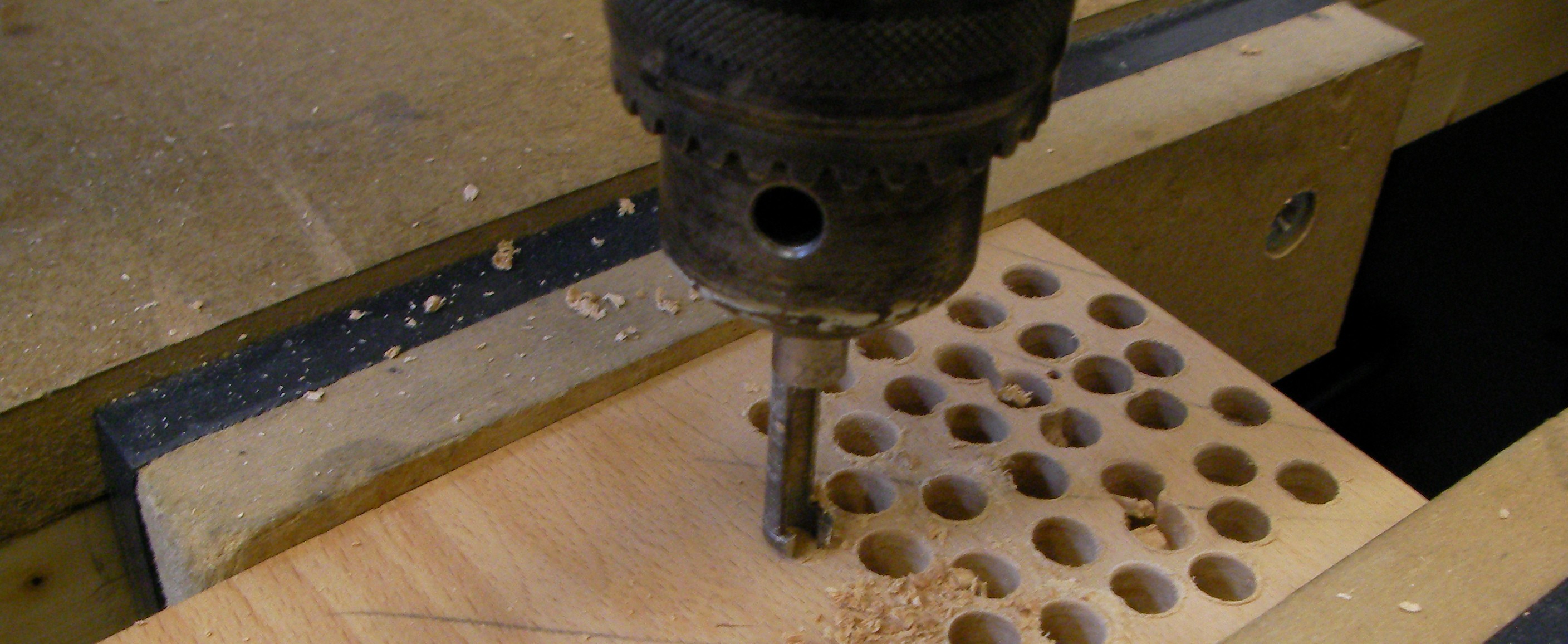

A fairly easy fix. First drill out the torn out screw holes…

Cut some hard-wood plugs….

Glue the plugs in the holes and cut the tops flush with a sharp chisel

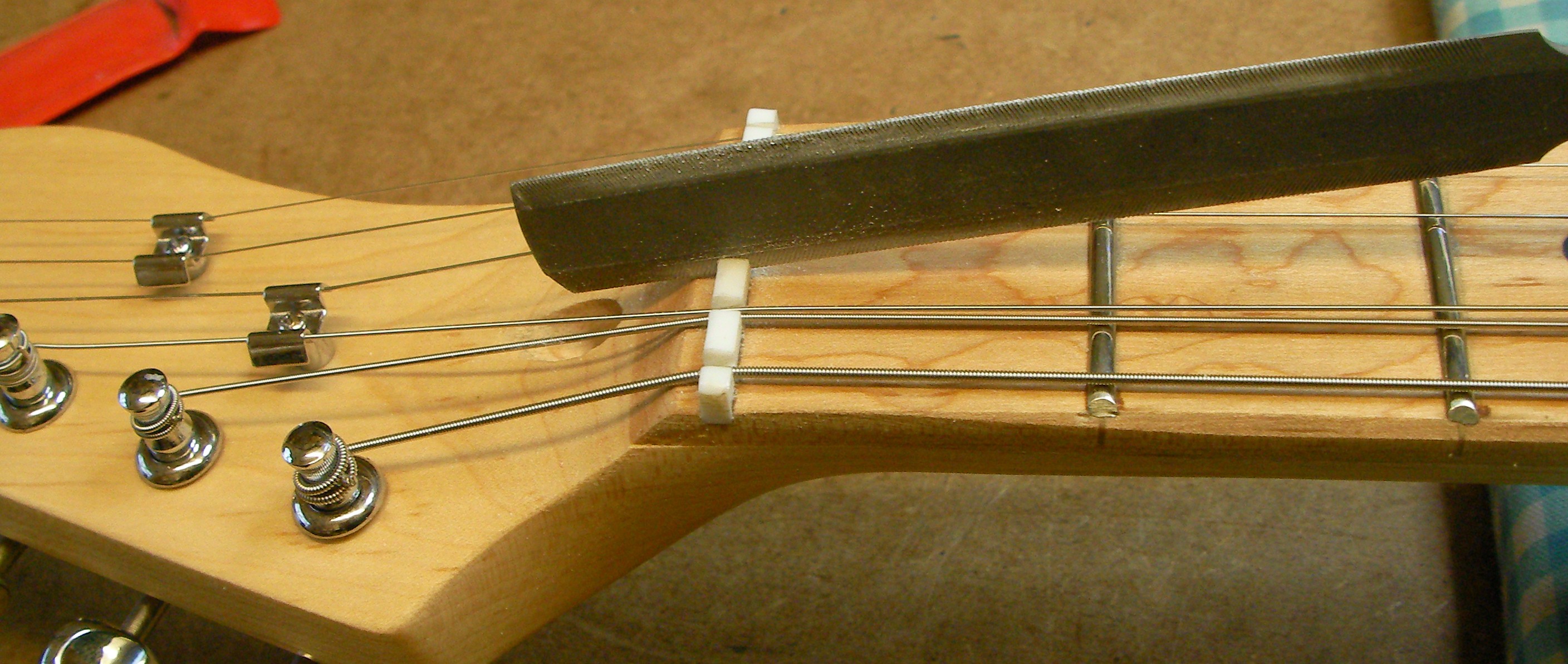

The neck pocket is a very sloppy fit so I clamped the neck in the pocket and used some thick thread in place of the two E-strings to line it up.

Drill new holes and fit new screws..

With the neck in place the angle is wrong. The action height is much too high, even without strings so that will have to be sorted later.

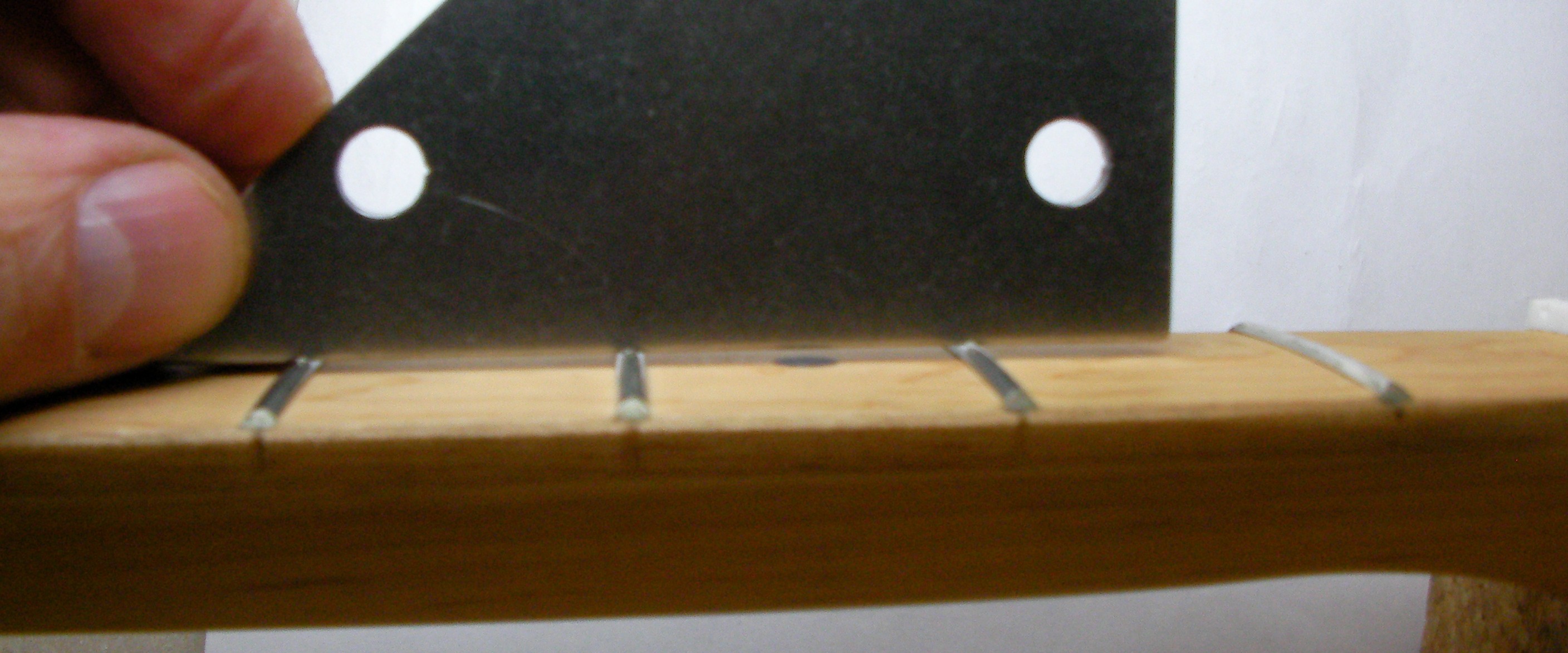

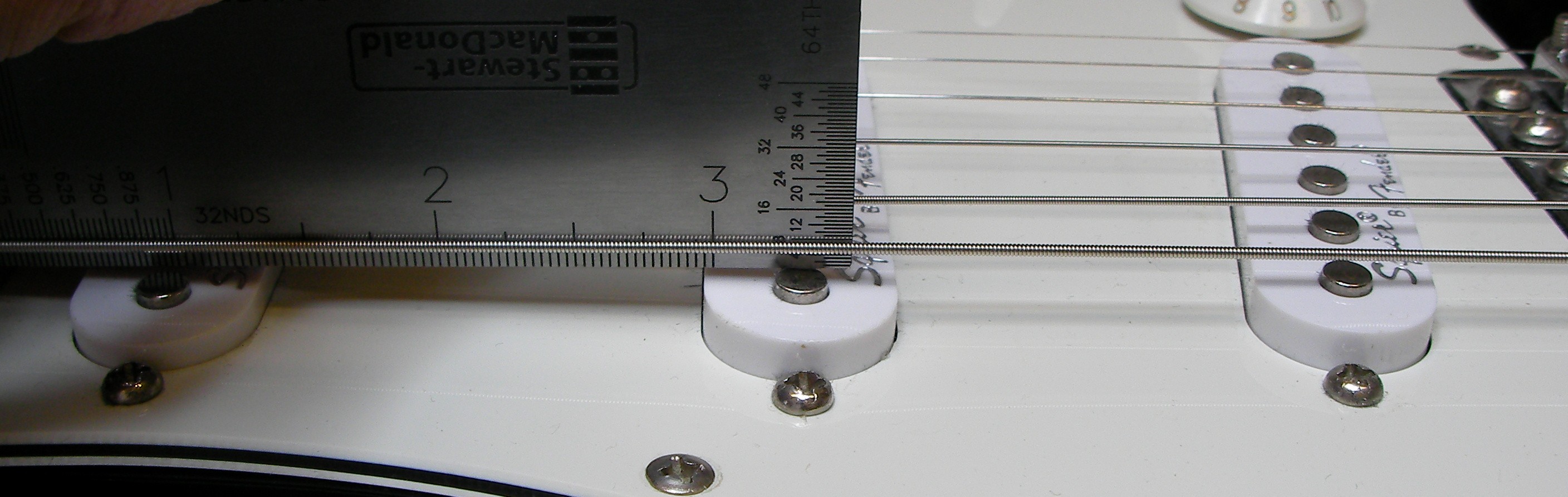

That’s actually the least of the problems. Running my fret rocker up and down the neck has exposed another major limiting factor with this neck. The frets are very uneven which means I’ll never be able to get a decent setup. To achieve that they need dressing first. I would actually always dress any new neck, even the high end stuff, it’s the secret of a really nice setup.

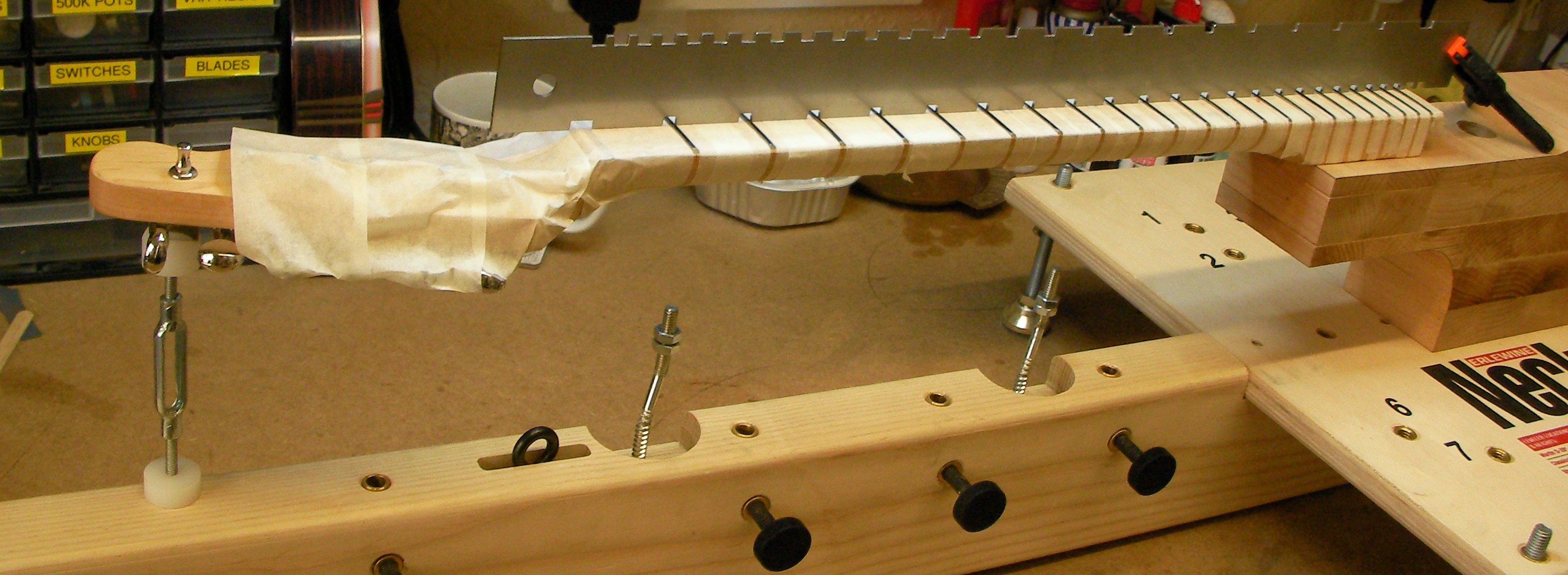

Not only were the frets very uneven but the truss-rod is stuck solid. There is a slight back-bow without the strings so I bolted it on the jig to level it before dressing the frets.

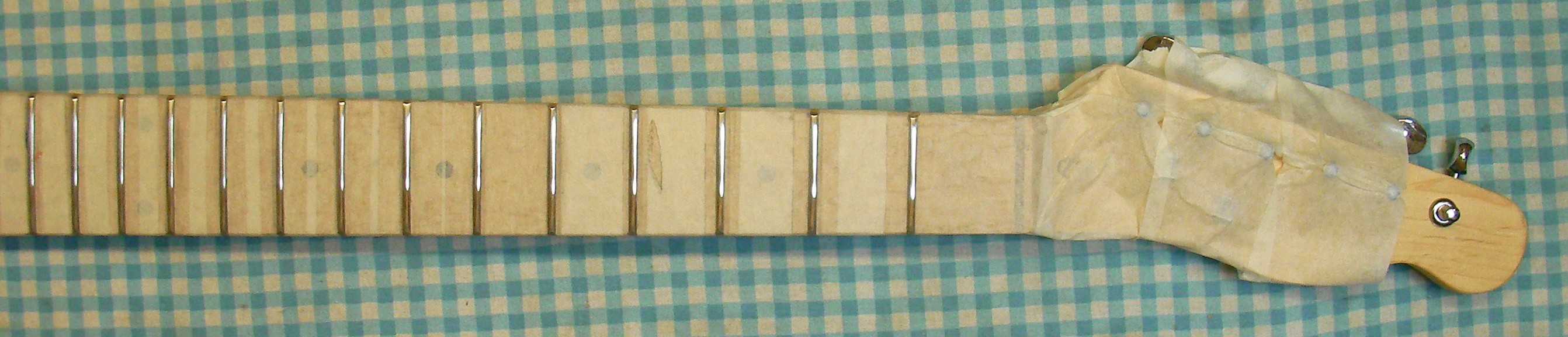

Once levelled I’ve re-shaped and polished them.

Cut a small shim to bring the angle of the neck back down.

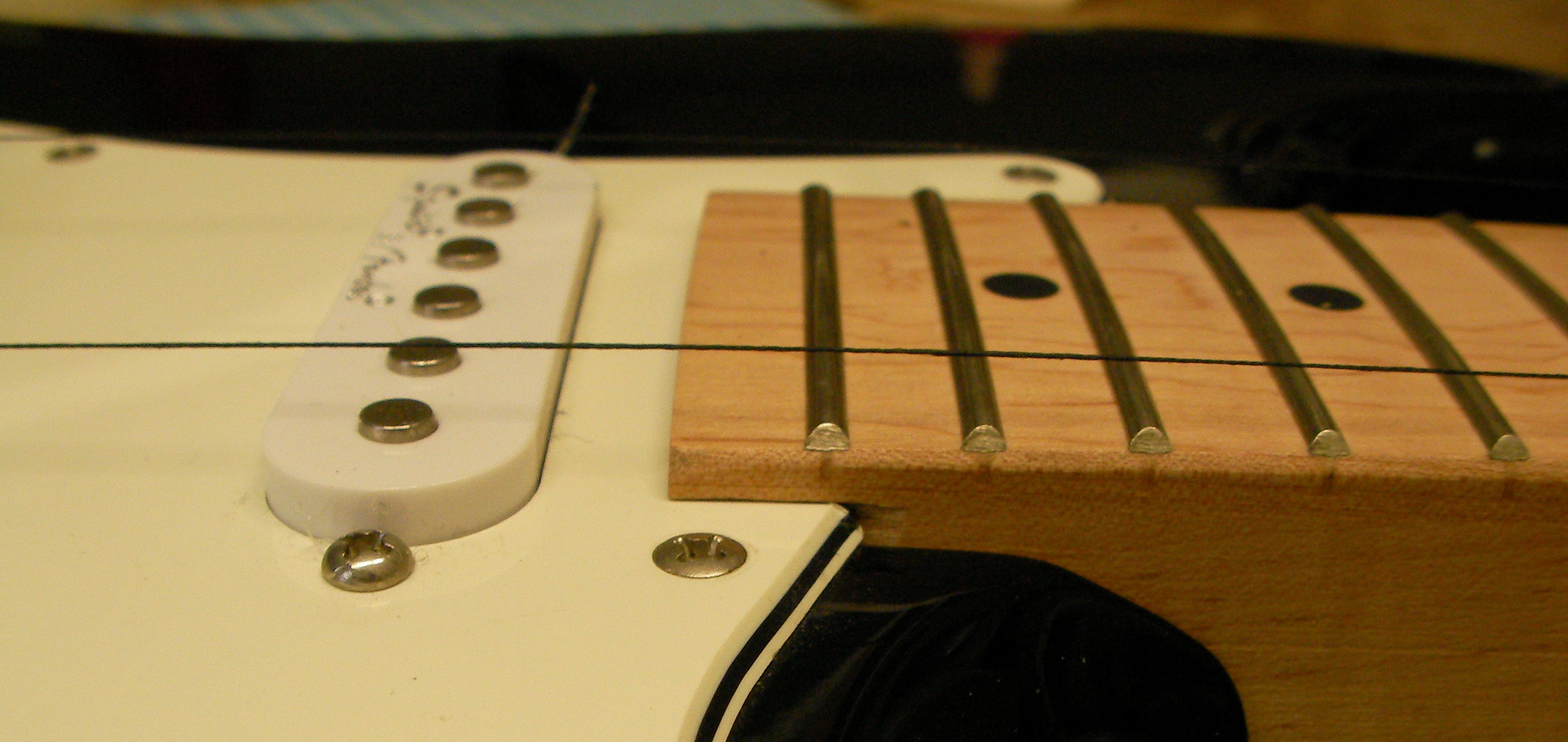

The nut isn’t a very good fit and the slots are way too high…

so I’ve cut them down to give a reasonable action at the 1st fret.

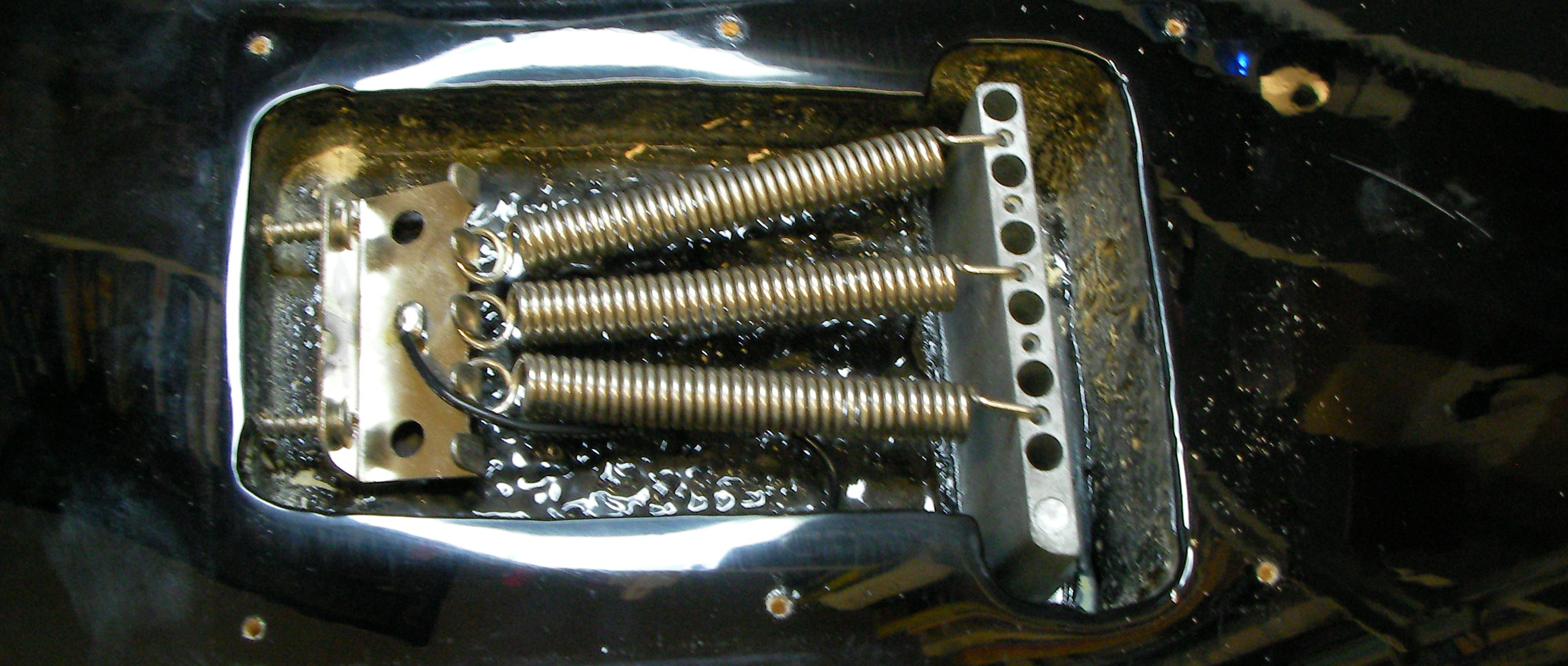

The tremolo springs were also set far too tight, the trem’ was sitting flat on the body and would only bend notes down and not up.

With the setup completed just reset the pickup heights and it’s all done.

The moral of the story… Bolting on a new neck is not quite as easy as you might think! There’s a lot more too it if you want it to play nicely. Buying a cheap neck can be a false economy as it will need a lot more work to get it set up properly.